1. Preface

Ultrasonic motor is driven by friction, stator piezoelectric stator and rotor contact, by rubbing rotor vibration for spinning force and the driving force. Although has the characteristic such as high torque, high control, can't tell from the principle of its faster than speed of vibration. The vibration of the piezoelectric vibrator maximum speed from hundreds of mm/s to several m/s2, past is not better than, the speed of ultrasonic motors. There is another important contact wear problem. Usually contact type ultrasonic motor is suitable for low speed high torque control applications, is not suitable for high speed rotation for a long time use. Here are suspended type ultrasonic actuator of stator and rotor is contact, rotor floating on top, its speed can reach the vibration speed of several times or even more than 10 times. Also appeared to replace air suspension platform of ultrasonic suspension platform. Without the air pump and pipeline through the power supply can be run, only make up the small integrated system. In this paper also make a vibration plate, on the other hand, floating on the surface of the smooth way.

2. The phenomenon of the near field acoustic levitation

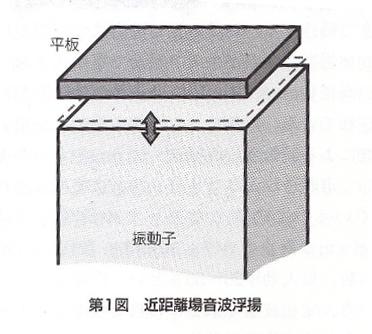

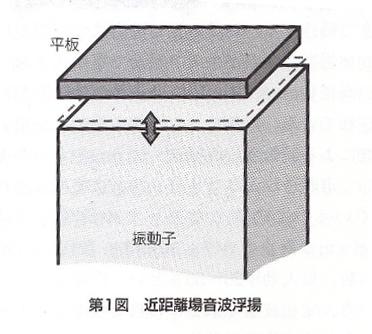

The technology is the use of the near field acoustic levitation phenomenon "contactless" was realized. The brief explanation of the phenomenon in the first place. As shown in figure 1 above on the surface of the ultrasonic vibration suspension for a tablet, suspension and vibration amplitude is proportional to the relationship, typically between several ten microns to 1 mm. Suspended objects weight increases suspended distance will be smaller. Inversely proportional to the square root of the board weight suspended distance. Board weight increased to a certain degree after will eventually come into contact with the vibration plate.

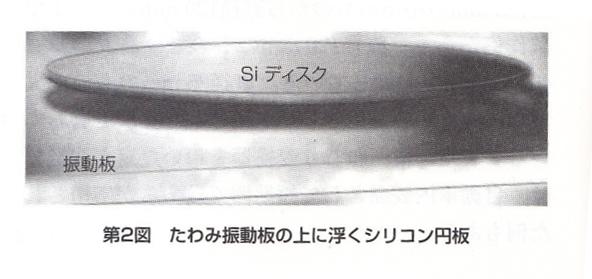

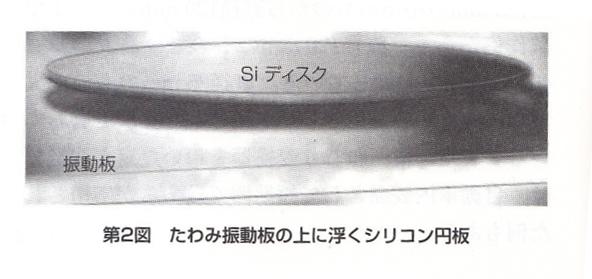

At this point, we imagine when suspended distance and vibration amplitude value (0 - p) being equal to the weight of the suspension, the largest area the size of the stamp can be suspended the weight of more than 100 KGF. Actually due to the vibration plane and floating plate exist the phenomenon such as bending, can the weight of the floating range should be smaller than the theoretical value, but also can guarantee to make most of the suspended objects. Figure 2 for bending vibration suspension silicon on the surface of circular plate. Can realize the piston vibration area is limited to one side or the diameter in the size of a quarter of wavelength, therefore suspended large objects will use bending vibration plate.

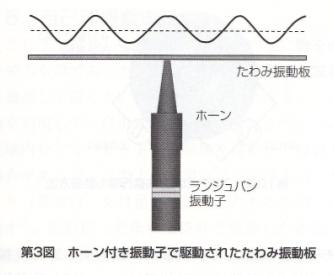

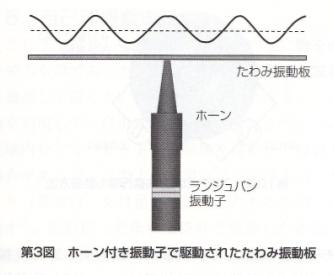

Figure 3 is the supplementary Angle of flute BLT transducer drive bending vibration plate, on the circular or rectangular metal plate for high frequency of bending vibration.

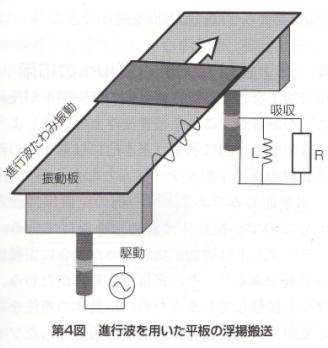

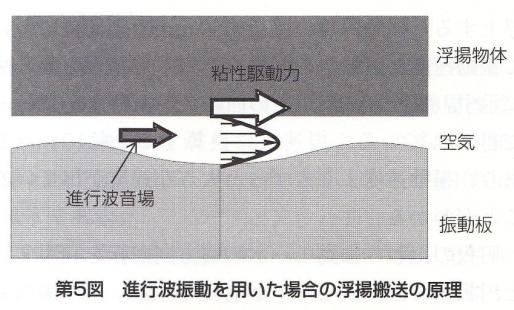

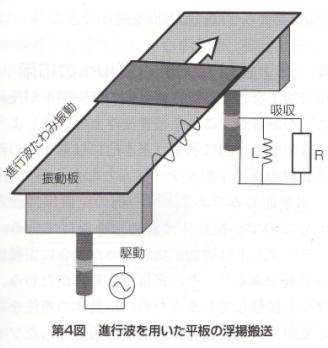

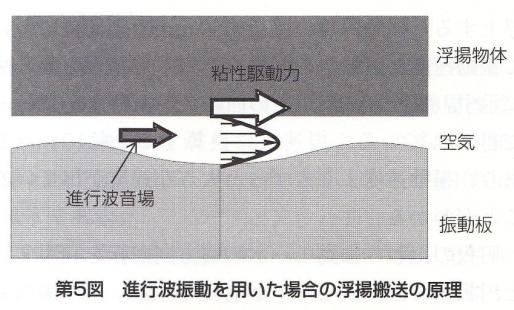

This phenomenon was used as a display circuit board with large glass non-contact transmission technology is being further development. Figure 4 long feet shape on both ends of the vibrating plate installed on the supplementary Angle of flute of piezoelectric vibrator, from one side drive, electrical loads connected to the other side make the bending vibration of traveling wave. Drive side power supply and load side impedance after exchanging, vibration propagation direction will be reversed. Objects using the vibration system, the tablet can be suspended in the air and is moving from the driver side electrical load side. Shown in figure 5 vibration plate and suspended objects in the air layer between the wave propagation direction of air flow. Suspended tablet guided by air flow to the horizontal direction. The resulting thrust with air viscosity, not a lot of thrust.

3. The application of suspension high-speed rotating motor

Objects by bending vibration plate tablet suspension and transfer the technology is further research, on the other hand, the application of this phenomenon is also in the further study of rotary motor and the mobile platform. To replace in figure 4 vibration plate with circle shape can be made into rotary type motor. As shown in figure 6, the interval of two vibrator for a quarter of wavelength, phase difference drive ring at 90 degrees can produce traveling wave. In the circle inside of the air gap into the rotor vibration. As shown in figure 7 rotor suspended after excitation vibration, vibration circle diameter of about 60 mm, figure 8 for the measurement of vibration velocity and the number of rotation relationship. More than 3000 times per minute the vibration of the rotating number can be 0.3 m/s speed. Conversion speed into a week, which is about 10 m/s. It can be seen that the structure can be much greater than the vibration velocity.

Application of circular bending vibration mode of direction to yuan plate type suspension motor. Shown in figure 9 is the same diameter circular plate for high speed rotating rotor in the process of suspension. Vibration of circular plate on the back of the adhesive has a circular piezoelectric ceramic ring. As shown in figure 9, quartiles electrode driven by two phase power supply. The vibration pattern still produce approximate weeks traveling wave in the direction of rotation and vibration.

In such a vibration mode, when driving phase difference of 180 degrees rotation direction will be reversed.

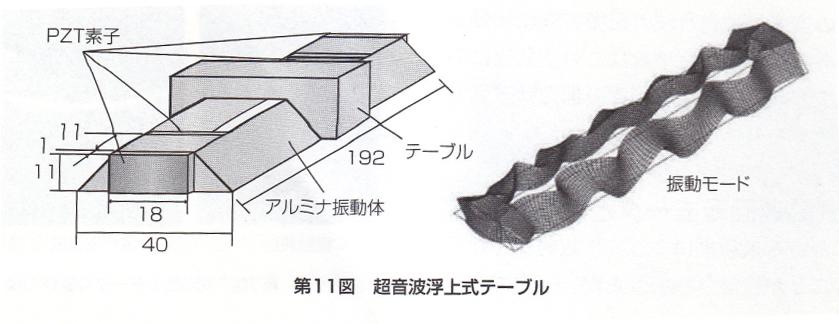

The application of linear platform 4. Suspension

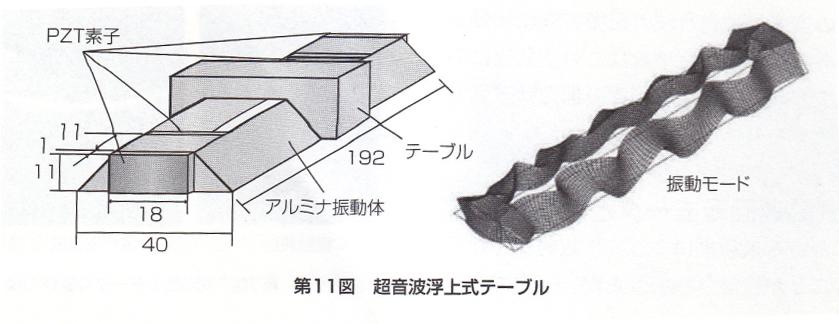

Air suspension platform are used in precision machining, figure 11 shows the alternative air suspension by ultrasonic levitation. The principle is similar to figure 4, just to transfer suspension device suspended tablet for the working platform. If only horizontal transverse position keeping ability would not be sufficient, so the vibration on slope is designed. In addition, the processed object is placed on working platform, combined with the vibration body weight when the sheet processed object when the bending vibration, and access to the working platform, so you need to ensure the vibration body has good rigidity. Cross section is a triangle made from high quality ceramic processing cutting. Piezoelectric ceramic plate bonding in vibration on both sides of the body, as shown by the piezoelectric vibration excitation. Driven by high quality ceramic for ultrasonic vibration body example is relatively small, but you can get sufficient vibration amplitude. Suspension working platform is the same material. This suspension working platform can reach 100 g weight capacity.

5. Automatic suspension transport table

Mentioned above were suspended on the vibration plate object technology. If it is in the ground of the smooth, place the vibrating plate reverse after vibrating plate itself will be suspended. Using the phenomenon, is developing an automatic type vibrating plate. Factory will use the pallet delivery of spare parts and other products, in figure 12 is automatically suspended type of pallet (loading) instead of the ordinary pallet. Loading is through the vibration plate and the soft material support. Glue the bending vibration of piezoelectric ceramic plate four load capacity can reach more than 10 KGF. Because the ground is usually bending is not smooth, can appear some part in practical use and the phenomenon of vibration plate exposure, but move the required traction only about one over ten of the cut. A vibrating plate power consumption for decades.

6. Summary

Introduces some application of near field acoustic levitation above phenomenon of non-contact type actuator, equipment, the application of the case. Most about driving frequency between 20 to 40 KHZ, with the highest frequency is below 100 KHZ.

Although this is not yet commercially available suspension actuator, but its characteristics of non-magnetic, without air compressor will be widely used in the future. By then, application requirements for the realization of the need for data simulation. For surface vibration and air clearance suspended objects in many cases cannot ignore the amplitude of the amplitude, so it is necessary to use mobile contact method can compute moment. Past the calculation method of the linear acoustic field is unable to do it, so you need to research and development and the corresponding numerical calculation method.