Pick to multi-channel high speed data acquisition system in the laboratory in the application of the distributed parallel control technology, developed the 32 channels, 12, top 50 MHZ sampling rate, precision can record more than 1, 000 per second full waveform acoustic emission event recorder. The system of comprehensive technical indicators are similar lab is in the lead in the world. This paper briefly introduces the key technology and main properties of the system.

Keywords acoustic emission of high-speed data acquisition parallel control

0 the introduction

Caused by the destruction of the rock is broken gradually developed, turned it from small to big, from sparse to dense, micro cracks connected aggregated into big fracture surface, fracture surface friction sliding instability, avalanche damage in the end. Acoustic emission is from rupture and the vibration signals of the friction source. Acoustic emission on small scale sample, lab controllable recreates the natural earthquakes, mining under the condition of the reservoir induced earthquake and development of disaster events, such as process and mechanism of rock burst. These disasters occurred in the deep underground, physical process is difficult to direct observation. Therefore, developed a high level of observation recording system, the acoustic emission research progress, has important scientific value and social significance.

Experiments show that the acoustic emission signal observation is very difficult. From the time and the frequency change is very big, because it happened from dozens of seconds, thousands of times to 1 second; Seen from space, to obtain meaningful AE distribution image, must achieve the positioning precision of millimeter; The strength of the AE signal at least above six orders of magnitude, frequency range covers from tens of thousands of Hertz to millions of Hertz frequencies (Xinglin, 1998). Therefore, in the rock mechanics laboratory, AE research almost become the most challenging work, full waveform AE observation also is one of the fastest and most expensive technology change (Byerleeet al., 1977, Satoh et al., 1997, Lei et al., 1998).

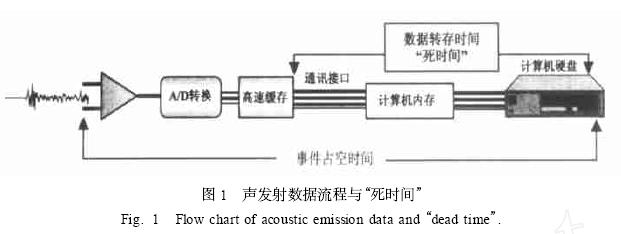

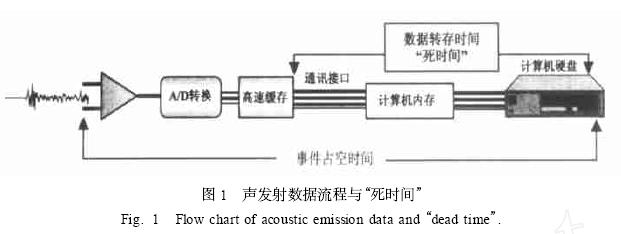

Sampling frequency and dynamic range and the channel number is a full waveform acoustic emission evaluation observation basic indicator of system performance. Since the 1980 s, with the development of the modulus conversion technology, the acoustic emission data acquisition frequency from 10 MHZ gradually increased to 40 MHZ, sampling resolution (or dynamic range) increased from 8 bit to 12 bit (li-qiang liu, 2000). As the growth of the acoustic emission space positioning demand, acoustic emission system on the number of sampling channel is expanding quickly, from classic eight channel up to 32 channels. These indicators improved effectively improve the precision of acoustic emission wave record, but also make the record data has skyrocketed. For example, if a waveform acoustic emission events recorded in the 80 s on the system to produce the amount of data that is 8 kbyte, then produce the amount of data on the latest system is likely to be 320 kbyte. All data needed from the data acquisition system of high speed cache, through the communication interface is transferred to computer on the external storage. Data transfer need to take considerable time, in the process of transfer, the whole acquisition system in the closed wait state. Traditionally, this paragraph of time is called the "dead time" (figure 1). Considering the instability of the rock damage phase, the acoustic emission incident frequency could reach thousands of times per second, possible emergent data volume will reach millions of bytes per second. From the cache to such huge amount of data in high speed transfer to the outside of the computer storage devices, will produce a lot of "dead time", greatly reduce the observation ability of acoustic emission system.

In fact, the previous acoustic emission system can only every second transfer data of several or dozens of acoustic emission events. Visible, the instability and failure of rock sample stage, they may have lost most of the acoustic emission data, so the follow-up study must contain very big deviation. If continue to use the original data transfer communication way, USES the index system of new sampling technology and produce greater amounts of data will make the "dead time" longer dozens of times, make the system almost completely lost his ability to do observation records. As a result, increase the speed of data transfer for acoustic emission observation system, become a new generation developed one of the key technical problems of acoustic emission observation system.

1 high-speed data transmission bus

Improve the acoustic emission observation system data transfer speed of primary technology is to use the appropriate data bus. Data transfer bus from transient signals AD converter cache to the exports of computer data transmission, used to be the biggest bottleneck of the influence on the speed of data transfer. In the 1980 s, earlier full waveform data acquisition system which USES the general low speed serial communication technology, such as RS232, IEEE488 and so on, the transmission speed far cannot satisfy the need, thus eliminated soon. To accelerate the speed of data transmission, acoustic emission system mostly later adopted in accordance with the special parallel interface bus standard specification, for example, ISA, EPP, etc. The parallel interface significantly improves the speed of data transmission, starting in the 90 s to the end of the 20th century, the death time of the acoustic emission from 500 ~ 600 ms gradually reduced to about 50 ms, which can record every second about 20 8 to 16 channels of acoustic emission events or point of full waveform. However, this is reaching the limit of this kind of parallel bus transmission (Winn, 1994). In order to further improve the transmission speed, at the beginning of this century, began to someone trying to use the PCI bus technology in parallel. The measured results show that it can only make the transmission speed and improve about three times the left and right sides, the development potential is not big.

Early USB1. 1 interface speed is slow, and EPP close, no practical value. Is widely used in recent years the USB2. 0 (universal serial interface bus) interface theoretically make speed increased 40 times, become a new type of transmission interface is the best choice for acoustic emission system. After the examination, the ordinary USB2. 0 interface using DMA transmission technology, the measured maximum speeds of about 17 mbytes/s (Xiao Shiwen, 2002). We developed a high-speed UD2MA piece of technology transfer, the transfer rate reached 32 mbytes/s. Look from the original design of USB specification, although it is very fast, but is mainly used in a large number of continuous transmission of a block of data or data flow transmission, therefore is mainly used in hard disk, digital camera, scanner and other equipment, not answer emission record type of this kind of frequent breaking of high precision timing small piece of data transmission. Through hardware and software design of upper machine and lower machine, we already have a dedicated control technology (U - USB2. 0), the data transmission of acoustic emission system to hold the USB high speed characteristics, and ensure the control accuracy of acoustic emission time.

The introduction of the USB interface technology, not only greatly improves the transmission speed, and as a result of this interface can be completely isolated external devices and computer bus, significantly improves the signal-to-noise ratio of data acquisition, it is very important in high speed data acquisition characteristics of excellence.

More than 2 bus parallel data transmission

The design goal of this project is 32 channel signal records, sampling resolution of 12 bit (each AD conversion number 2 bytes of storage). To record length is 4 kword (8 kbytes) calculation, system triggering record at a time, will generate 256 kbyte data in 32 channels. If the rock burst phase, 1 000 times of acoustic emission events per second, then a second produced by the sudden according to total amount could reach 256 mbytes. So, although U - USB2. 0 can make the transmission speed increased to 32 mbyte/s, but the requirements with observations to a considerable gap.

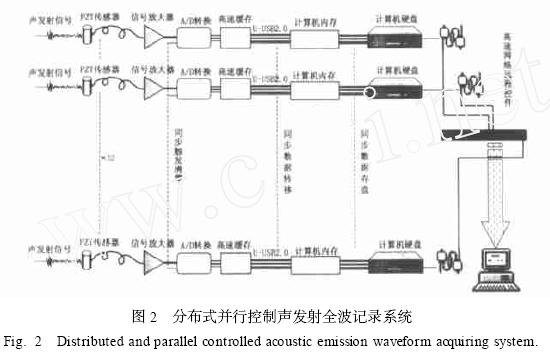

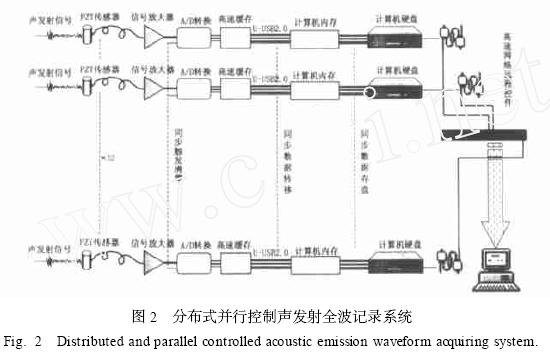

Basic traditional acoustic emission system using a single data communication interface, each time the record is complete, all of the data channel through which an interface by transmission to the computer peripheral storage device, the interface speed put forward high request, there is no kind of performance can choose appropriate technology. To solve this problem, we set up a parallel control computer fleet sampling system, for each data acquisition channel provides a separate high-speed data communication interface, a single file, controlled by a dedicated computer independent, more into a control unit with multiple signal channels of data acquisition unit (figure 2). The technology exponentially expanded the width of the data bus, thus improves the throughput of data also multiplied. 1 set which is composed of 32 counter fleet of transient data flow can reach 1, 024 mbytes/s, able to adapt to the need of acoustic emission observations.

The original integration in 1 case of multiple data acquisition channels assigned to multiple machines, the most main problem is how to ensure synchronization between each channel. Synchronization problem can be divided into two aspects to consider: one is in the condition of high speed data acquisition of real-time control synchronization, the other is in the condition of system parameter setting, the database management of information sharing in sync. Use OL E (Object Linking and Embedding) technology is the development of remote control system in synchronous operation of the unit. In running state, system to produce 2 ~ 3 ns pulse switch, parallel control of the board of synchronized trigger and the reset action, ensure the synchronization time error is less than one sampling interval. In addition, the system through the high speed switch board, also provide 2 mu s switch instructions, parallel control process of data transfer and save all the sampling units. Trigger and reset switch instructions to ensure in the shortest possible sampling interval 20 ns on parallel sampling synchronization precision, data transfer and save the instructions to ensure the sampling length in the shortest possible 20 mu s (with 50 MHZ, 1, 024 points) on the accuracy of the concurrent process synchronization. In the condition of parameter set or database management, control of each unit through high-speed LAN mutual dialogue, information and data packets with millisecond speed passed between them, the system operators are free to set operation parameters or call management database.

As a kind of high speed data acquisition system, acoustic emission monitoring device reflects the contemporary latest electronic technology in the application of rock mechanics and earth's physical simulation experiment, has been the international competition in the hot spots. Because China's components production technology lags behind, the laboratory to buy foreign equipment is given priority to, for many years in this field we can only try to trace the footsteps of others, but not beyond. Although we couldn't a breakthrough on the device performance, but on the structure and system design can take a path of independent innovation. The project is on introducing the international latest device, on the basis of all the software and hardware independent design and development. By actual test, the system on the dynamic range of 12 bit, the fastest can record 50 MHZ sampling frequency vibration wave of acoustic emission sampling length from 2 kword to 32 kword is adjustable, the system is made up of 32 sampling channel.

System USES the distributed parallel control technology, greatly improve the efficiency of data transmission, the "dead time" is expected to less than 1 ms. Completion of this system will make China in observation of acoustic emission technology reach the world leading position.

The system of data acquisition and time synchronization part of the hardware technology development work done by Liu Zhiliang, USB data interface section completed by Zhang Zhihe, thank.

References (abbreviated)