Pick to: under the condition of uniaxial compression, were studied and analyzed the natural water, flooding saturated and seepage of the rock acoustic emission characteristics. Research shows that: in low stress stage, the seepage can not cause AE activity, usually in uniaxial pressure reached 60% ~ 80% of rock strength, closer to the damage, seepage and seepage moment will stop produce larger AE events, from stable seepage seepage generally receive no obvious AE signals to stop; Deformation characteristics of rock under the action of load and the acoustic emission phenomenon in the process of closely related. From the perspective of the average significance of energy and deformation analysis, it is concluded that the average energy change is in the process of deformation in the specimen and the average burst synchronization, flooding the average energy of the rock saturated rocks from natural water cut is small, the average large deformation, and according to the rock failure damage mechanism to explain.

Key words: acoustic emission; The average energy; The average deformation; Uniaxial compression; Failure mechanism

1 is described

Rock Acoustic Emission (& Emission, AE) refers to the internal lattice in the process of rock material under load deformation dislocation or micro crack propagation caused by the phenomenon of instantaneous elastic wave [5]. In the early 1930 s, Obert and Duvall is found in rocks acoustic emission phenomenon [3]. Rock acoustic emission phenomenon of produce and rock deformation and failure process of the change of strain energy. It is generally believed that because most of the rock brittleness material and its inner crack extension show the agglomeration after the sudden release of energy, and generate elastic stress wave (sound waves), which is the source of AE energy. In the AE signal by the vibration source place to Po process, through monitoring and analysis of the elastic stress wave, understand the laws of rock in the process of stress crack development, provide the basis for field observation and prediction.

In wuhan geotechnical Chen new homemade joint plane shear seepage test machine, such as the structure of the marble surface development in the natural water, flooding saturated seepage 3 (flooding about 130 h) and applied under the condition of uniaxial compression test, and introduce the average energy of acoustic emission and the average deformation, analyzed the different conditions of rock test results.

2 laboratory equipment, loading method and rock specimens

2. 1 laboratory equipment

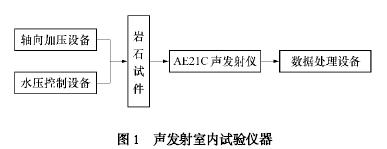

The whole test system by the joint plane shear flow tester, AE21C acoustic emission instrument, seepage of water tank and adjust the water pressure of nitrogen gas bottle, applied axial load is composed of 50 t jack and other auxiliary equipment. Test, the application of 20 kHz and 10 kHz broadband probe acoustic emission signal, with 20 kHz probes collect AE waveform, at the same time using AE21C acoustic emission instrument automatic high speed sampling, recording acoustic emission signal. As shown in figure 1.

AE21C acoustic emission system of sampling frequency can be up to 2 MHz, it supports fast Fourier transform (FFT), correlation analysis and transfer function of digital signal processing, can be directly statistics of AE energy rate per unit time, hit count (each collision is a complete AE waveform, therefore, can be understood as the counting), ringing counting, and the corresponding frequency value of amplitude. The test of the sampling frequency of 2 MHz.

In order to avoid friction due to the end of the specimens in the load and noise interference, in the end a little vaseline sample, and at the end of specimen cushion rubber gasket. Acoustic emission probe with elastic fixed to the specimen after smearing vaseline coupling parts accordingly. In order to avoid the interference of mechanical vibration, the application of 50 t jack manual pressure. At the same time, in order to reduce the influence of noise should maintain the experimental environment quiet.

2. 2 rock specimen processing

The test specimens taken from cockscomb mouth gold mine, samples of marble in the development of structural planes. Specimen by cutting, be processed into 50 mm x 50 mm x 100 mm rectangle, the parallelism, smoothness and finish all conform to the requirements of the test procedures.

Structural plane development marble grain fine, dense, soft texture, structural plane in siliceous fillings.

3 loading way 2.

Test, the constant loading speed to 0. 25 ~ 1. 0 kN/level uniaxial pressure, in the process of the stabilized collection AE signal. Considering seepage coupling effect, application of the specimen nozzle under seepage of water, using water tank and the nitrogen cylinder to adjust the water pressure. In the center of the special nozzle on the surface (30 mm in diameter), spray evenly decorated with the ring and radial sink, slot 3 mm wide. Pad in a uniform along the nozzle rubber gasket groove on the nozzle holes, so that water mist evenly infiltration specimen. Due to the rubber gasket peripheral is not opening, add 1 ~ 2 MPa uniaxial pressure, rubber gasket can also play the role of sealing water mist, so as to avoid leakage of water mist along the contact surface.

Rock occurred after the initial damage per level voltage stabilizing after about 30 s, 60 s collected without seepage of AE signal, and then applying 0. 2 ~ 0. 4 MPa water pressure, collected 60 s and seepage of the AE signal at the same time.

3 AE characteristic analysis of natural water cut marble

AE21C acoustic emission system, was applied to 20 kHz bandwidth probe FFT transform, with the AE signal waveform of the output every time the impact of each waveform) (frequency and amplitude, and statistical ringing count rate and impact energy count rate and count rate.

The introduction of a single ring average energy and average deformation of a single ring. Single ringing the average energy (hereinafter referred to as the average energy) = count rate/ringing count rate, used to characterize the rock specimen with single ring average energy, reflect the amplitude of the ring. Single ringing the average deformation (hereinafter referred to as the average deformation) = the average energy/load stress of single ring, according to the force displacement of x = work and function transformation theory, the value can be used to characterize the ringing count rate per unit time, along with the release of rock deformation stress wave.

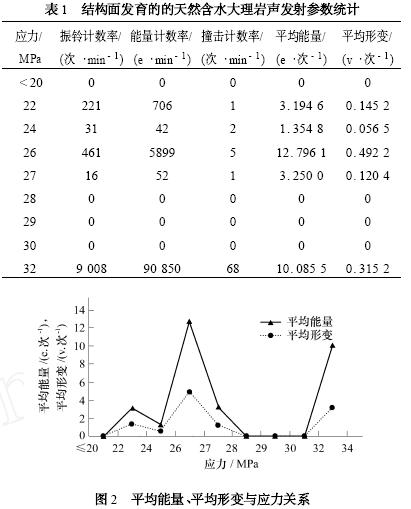

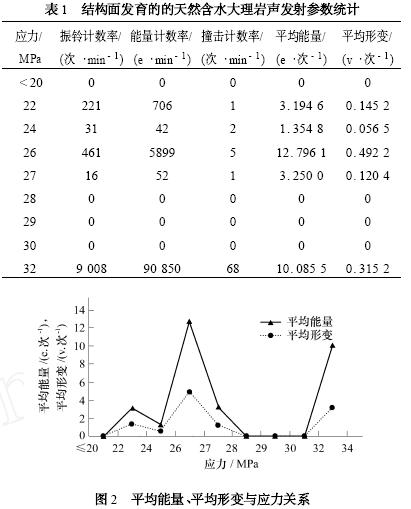

Part of the results are shown in table 1 and figure 2. To facilitate said on the same figure, the average deformation by the data in table 10 x magnification.

At the beginning of the test load, monitor no AE signal output, until the stress reaches about 65% of the rock strength, began to appear AE signals, after quite some time less than AE signal monitoring; When the stress load to about 80% of the rock strength, you will be presented with a large number of AE signal, at the same time specimens in preliminary burst; Since then to the specimen damage will appear a large number of AE signals.

In the process of test, through the macroscopic observation, record rock stress level in all stages of damage at the same time. Through test observation found that natural water-bearing rock when the stress reaches 26 MPa, start first burst; When the stress reaches 32 MPa, rock specimen began to a wide range of burst; When stress to the 33 MPa, rock specimen will not be regulated and eventually destroyed.

Can be seen from table 1 and figure 2, the average energy in the process of deformation in the specimen and the average fracture changes are synchronous, with periodic. During initial crack average energy and deformation are the biggest, in the stage of release is mainly the average stress wave amplitude is larger. In the destruction of the voltage phase, the average energy and the average deformation is small when the initial crack, in the stage of release is less average amplitude of stress wave. New crack appeared a lot of rock, therefore, the internal (i.e., the initial rupture, stress level corresponds to 26 MPa), the average energy release of the acoustic emission maximum; Rock rupture range (stress level corresponds to 32 MPa), average every time the energy release of the acoustic emission times; Rock start preliminary expansion or internal crack initiation (stress level is less than 22 MPa), the average energy release of the acoustic emission is small; In no voltage phase of stress level is more than 33 (MPa) is mainly along the shear failure surface of sliding are formed, the average acoustic emission energy is smaller.

Figure 2, the average energy and average deformation and pressure distribution can be explained by rock deformation and failure characteristics. When stress is less than 20 MPa, no monitoring to the AE signal, which corresponds to the fracture pressure of the stress - strain curve and linear elastic stage, mainly native rock crack closure and elastic compression; Pressure reaches 22 MPa, native rock crack initial extension, the average energy release of the acoustic emission is relatively small, inspire a handful of small amplitude of stress wave; Pressure reaches 26 MPa, rock initial burst, produced a large number of micro cracks, and continuously expand, the average energy release of the acoustic emission is the largest, inspire more large amplitude of stress wave; Pressure reaches 32 MPa, a wide range of rock burst, the average energy and the average deformation is smaller than the initial burst, the fracture is mainly along the main crack, inspired a large number of relatively small amplitude of the initial burst of stress wave. In the process of rock specimen deformation fracture, crack extension

Relative has periodic, sudden. Average energy (deformation) ~ pressure distribution reflects the natural water-bearing rock deformation and failure starts from the tensile fracture of crack expansion, after the crack expansion adjusted to a certain stage, the damage of the rock is transformed into cracks along the main direction of shear failure (crack through).

4 flooding saturation marble AE characteristics analysis

Around for a long time (130 h) after soaking, marble apparent softening of the development of structural plane stiffness reduce, showing a gradual damage characteristics, and receives the AE process is complete.

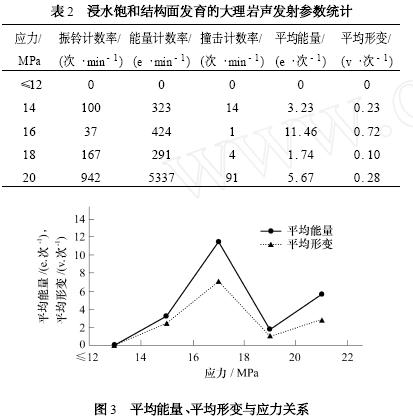

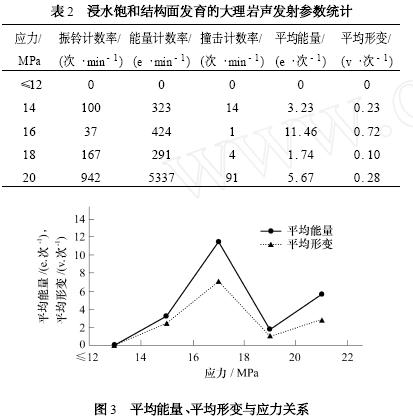

Application AE21C system for 20 kHz bandwidth probe acquisition of AE waveform FFT transform, each time the output waveform frequency. Part of the results are shown in table 2 and figure 3.

Can be seen from figure 3, the AE signal at the beginning of the load to produce and receive less. The initial burst, AE signal has increased dramatically. Rock damage more intense, the AE signal increase are more severe.

From table 2 and figure 3, you can see that flooded the average energy of saturated rock deformation in the specimen and the average fracture change is also in the process of synchronization.

Observed: flooding saturated rocks in 20 MPa pressure, started the first burst; When the pressure reaches 22 MPa, began to a wide range of rupture. Compared with natural water-bearing rock, found that after immersion saturated rocks from the first time to the large scale bursts, pressure increased by only 2 MPa, than natural water-bearing rock from first to large scale bursts of 6 MPa pressure small 4 MPa, this phenomenon shows the development of structural plane marble by water softening is very significant, start first burst of flooding the deformation of saturated rock burst are natural water-bearing rock be sensitive to stress changes.

Five different water-bearing rock stress contrast average energy (deformation)

Comparing figure 2 and figure 3 and table 1 and table 2, the average energy of rock can be found that affected by water stress (strain) relationship relatively simple natural water-bearing rock specimen. Began to appear under the stress of the smaller AE signal, the initial crack and wide-ranging rupture stress level is significantly reduced, show very significant rock specimen by softening action of water, again after the water softening rock expansion was highly sensitive to the stress changes of the internal crack.

Comparison of structural plane development marble specimens in different water cut conditions in the scope of initial crack and large bursts of average energy, it can be seen: in native rock crack initiation stage (corresponding to 22 MPa and 14 MPa), single ring, on average, the energy released by no obvious difference; Inside the rock crack of extension stage (corresponding to 26 MPa and 16 MPa), natural water-bearing rock has begun initial burst, and flooding of saturated rocks until 20 MPa to initial burst, this may be due to rock water softening significantly, has the tendency of creep, and that the softening of rock deformation and failure intensity than natural water-bearing rock because of the relatively less.

Compare rock average deformation can be seen in all stages of deformation: the average deformation of saturated rocks is natural water immersion rock, further verify the structural plane of marble by water softening significantly, that has a tendency to creep.

Through the experiment process of observation, found that more than caused flooding saturated rocks and natural water cut the average energy (deformation) of the rock stress distribution differences may be the cause of natural water-bearing rock is immersed saturated brittle rock, the damage begins with tensile fracture of tensile damage, to the main crack to begin to form gradually transformed into a shear failure, so that the deformation and failure is flooding saturated rocks is intense, with sudden, embodies the marble of the structure of natural water surface development has the characteristics of brittle failure. The deformation and failure characteristics of natural water rock for AE monitoring. Flooding the structure of the saturated marble by water softening effect of the development of surface deformation and failure tend to be much earlier than natural water-bearing rock shear failure and deformation in each stage of its deformation is bigger, to be progressive, its damage degree weakens, easier for deformation observation.

6 "language

Through experimental research, can draw the following conclusions.

(1) the rock specimen are in a low stress level, the AE signal is very weak. Stress level must reach a threshold value or energy must accumulate to a certain amount to be inspired to make monitor accept to AE signals.

(2) flooding after saturation, marble structure surface development of AE signals were generally rich natural water condition; During initial rupture and a wide range of the average deformation is natural hydrated rocks have increased obviously, easy for deformation observation and prediction. This is due to the structural plane marble water softening that are sensitive to stress, a creep tendency.

(3) rock acoustic emission phenomenon is closely related to rock internal deformation and failure, the average energy (deformation) further and the relationship between stress and the rock AE process has obvious stages, the average energy in the process of deformation in the specimen and the average fracture change is synchronized.

References (abbreviated)